It is widely known that sapphire materials are commonly used in watches, such as sapphire watch crystals, bezels, dials and cases. But can sapphire be applied to laser beauty devices? The answer is yes. Today’s article introduces

The application of sapphire by Sun Yin Crystal is guiding light for laser beauty devices.

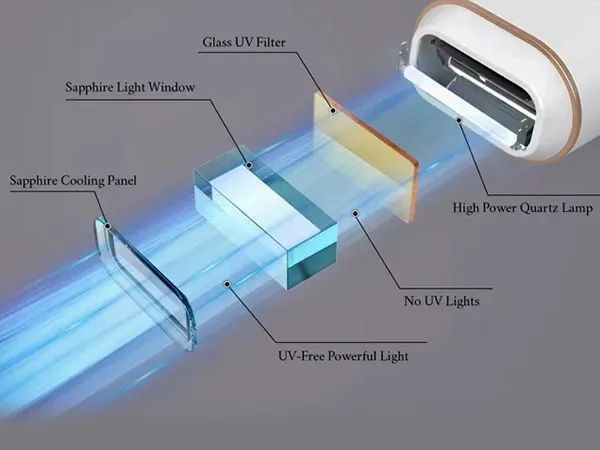

Hair removal devices, as one type of laser beauty product, have attracted Widespread attention as convenient home-use equipment. One of the cores Components of these devices is the sapphire light guide block. The Sapphire Light guide block effectively transmits the energy generated by the light source to The skin surface, achieving the hair removal effect.

Thanks to its excellent performance, particularly its light transmittance and high-Temperature resistance, sapphire material demonstrates unique application value in the field of light block for hair removal devices.

**The material sources comes from the internet*

Working Principle of Hair Removal Devices and the Role of Light Guide Block

Hair removal devices commonly available on the market primarily work by using specific wavelengths of light to irradiate human skin. The melanin in hair follicles absorbs the light energy and converts it into heat energy, which destroys the hair follicle tissue and inhibits hair growth.

During this process, the light emitted by the light source needs to be transmitted and evenly distributed through a light guide block. This ensures that the light energy reaching the skin’s surface is both uniform and sufficiently strong, enabling effective action on the hair follicles.

If the performance of light guide block is subpar, it may result in energy loss during transmission and uneven distribution. This would decrease the effectiveness of hair removal and , in severs cases, could even cause localized overheating of the skin, leading to adverse effects.

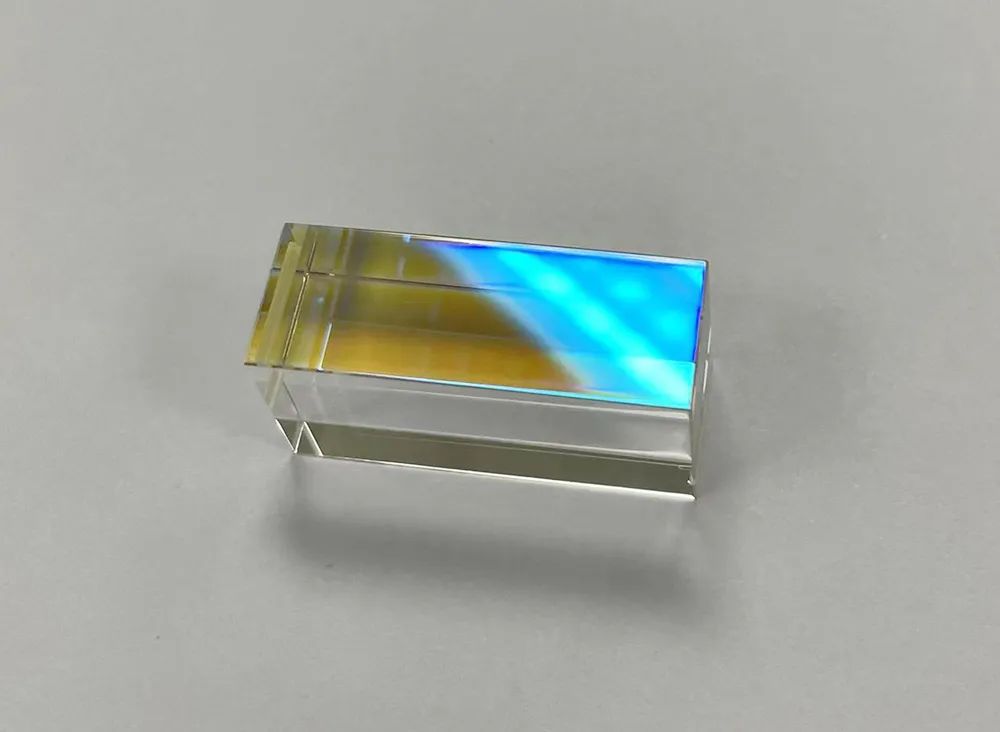

*The picture shows the the sapphire light guide block of the laser beauty instrument customized by Sun Yin Crystal for customers

Performance Advantages of Sapphire Material

1. Optical Performance

Sapphire material has an exceptionally high transmittance in the visible and near-infrared light spectrum, typically not less than 84.5%. This allows the specific wavelength of light guide block, minimizing energy loss and ensuring sufficient energy reached the skin’s hair follicles.

2. Physical Performance

High Hardness: The hardness of Sapphire material is second only to diamond, with a Mohs hardness of 9. Despite frequent contact during the use of hair removal devices with objects such as cleaning tools, skin oils and dust, the high hardness of sapphire light guide block ensures scratch resistance and wear durability. These characteristics enable the product’s surface to maintain smoothness and optical performance for a long time, significantly extending the lifespan of the light guide block. In comparison, lower hardness materials are prone to scratches after some times, which can affect light transmission.

Thermal Stability: During operation, the light source generates substantial heat, and the guide block absorbs part of this heat. Sapphire, with an excellent melting point of 2045°C, demonstrates remarkable thermal stability, allowing the light guide block to function steadily under high temperatures without deformation or degradation.

3. Chemical Performance

Sapphire possesses excellent chemical stability and hardly reacts with common acids, alkalis and other chemical substances. In the usage environment of hair removal devices, it may come into contact with

Skin secretion like sweat, skincare residue and cleaning agents. Sapphire light guide block resist corrosion from these chemicals, maintaining their physical and optical stability.

Processing and Manufacturing Techniques for Sapphire Light Guide Block By Sun Yin Crystal

Due to the high hardness and brittleness of sapphire, its processing presents certain challenges. The manufacturing process for sapphire light guide blocks Involved precise cutting, grinding and polishing techniques. For instance, advanced equipment such as diamond wire saws is used during cutting to ensure flatness and accuracy. Grinding and polishing processes require specific abrasives and polishing agents, gradually reducing surface, meeting highlight transmission requirements.

Moreover, strict control over processing temperature and pressure is essential to avoid defects like cracks caused by thermal or mechanical stress during manufacturing.

Sun Yin Crystal Industry (Shenzhen) Co., Ltd., a manufacturer of sapphire products, is one of the drafting units for China’s synthetic sapphire glass industry standards. With 30 years of experience in Sapphire research, production and manufacturing, the company boasts comprehensive facilities and is among the few in the market with complete production processes from raw material (Sapphire crystal growth) to post-processing (silk screening, electroplating and coating).

Certified in ISO9001 quality management in 2008, the company also holds

REACH and RoHS certification, giving it a strong competitive edge in the market. the custom sapphire light guide blocks for laser beauty devices by Sun Yin Crystal is rectangular glass with all six sides optically polished. One end is coated with a cut-off filter film, typically blocking light below 575nm while transmitting light between 600nm and 1200nm. The transmitted light is totally reflected within the block and exits through the opposite end, irradiating the skin for laser beauty treatment. Customers with relevant needs are welcome to inquire for more information.